I've been struggling with inconsistent coffee basket dimensions that ruin our customers' brewing experience. After countless complaints about ill-fitting baskets, I needed reliable manufacturing standards.

When importing custom coffee baskets from China, standard dimensions typically include rim diameters of 51-58mm, depths of 20-40mm, wall thickness of 1.5-3.0mm, and base thickness of 2.0-5.0mm. Typical tolerances range from ±0.10mm to ±0.30mm depending on the specific dimension and manufacturing process.

Let's explore these specifications in detail to ensure your next custom coffee basket order meets your exact requirements and provides the consistent quality your customers demand.

Can I Define My Own Tolerance Stack-up for Critical Dimensions on My Drawing?

When I first started importing coffee baskets, I assumed manufacturers would follow my specifications exactly. However, I quickly learned that clear communication about tolerances is absolutely essential.

Yes, you can define your own tolerance stack-up for critical dimensions on your technical drawings. Manufacturers in China will follow customer-specified tolerances if they're clearly indicated on engineering drawings and fall within their manufacturing capabilities. This customization is essential for ensuring proper fit and functionality.

When creating your technical drawings for custom coffee baskets, it's important to understand how tolerance stack-up1 works. Tolerance stack-up refers to the cumulative effect of individual part tolerances when multiple components are assembled together. For coffee baskets, this is particularly important when considering how the basket will fit into portafilters and how tampers will fit into the basket.

Understanding Tolerance Stack-up

In manufacturing coffee baskets, several critical dimensions2 interact with each other:

- The rim diameter tolerance affects how the basket fits into the portafilter

- The inner diameter tolerance affects how the tamper fits into the basket

- The depth tolerance affects extraction consistency and dosing capacity

- Wall thickness tolerance affects strength and heat transfer

For optimal results, I recommend using geometric dimensioning and tolerancing (GD&T)3 principles on your drawings. This system provides a more comprehensive way to specify tolerances that account for the functional relationships between features.

Best Practices for Specifying Tolerances

| Dimension | Standard Tolerance | Tighter Tolerance (Premium) | Notes |

|---|---|---|---|

| Rim Diameter | ±0.20 mm | ±0.15 mm | Critical for portafilter fit |

| Basket Depth | ±0.30 mm | ±0.20 mm | Affects capacity and extraction |

| Wall Thickness | ±0.15 mm | ±0.10 mm | Impacts durability and heat transfer |

| Base Thickness | ±0.10 mm | ±0.07 mm | Affects filtration and flow rate |

When specifying tolerances on your drawings, consider these tips:

- Clearly mark critical dimensions with tighter tolerances

- Use reference dimensions (marked with REF) for non-critical features

- Include datum references to establish clear measurement points

- Specify material requirements that can achieve your tolerances

- Consider functional testing requirements in addition to dimensional tolerances

Remember that tighter tolerances generally increase manufacturing costs. I've found that working closely with the manufacturer during the design phase helps identify which tolerances truly matter for functionality versus where you can save costs with standard tolerances.

What Metrology Will You Use to Verify My Dimensions During FAI?

I once received a batch of coffee baskets that seemed perfect until we tested them - the rim diameter varied by almost 1mm! I learned that knowing how measurements are verified is just as important as specifying the requirements.

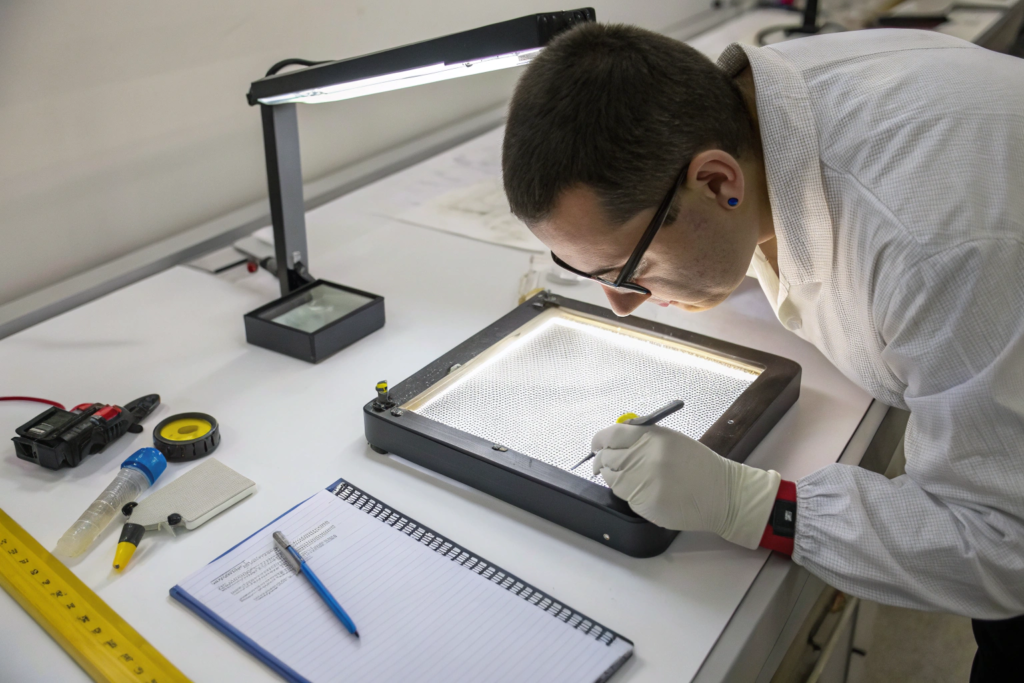

During First Article Inspection (FAI)4, manufacturers typically use Coordinate Measuring Machines (CMMs)5, digital micrometers6, calipers, and height gauges to verify coffee basket dimensions. For premium precision baskets, optical measurement systems7 provide non-contact verification of critical features like filter holes and surface profiles.

The metrology methods used during First Article Inspection (FAI) are crucial for ensuring that your custom coffee baskets meet your specifications before full production begins. As someone who has worked with various Chinese manufacturers, I've learned that understanding their measurement capabilities is essential for quality assurance.

Common Measurement Tools and Their Applications

Different measurement tools are used for different basket features:

Digital Micrometers and Calipers

These tools provide accurate measurements for basic dimensions like wall thickness and rim diameter. Most quality manufacturers use digital micrometers with resolution of 0.001mm, which is suitable for most coffee basket tolerances.

Coordinate Measuring Machines (CMMs)5

For premium coffee baskets, CMMs provide highly accurate 3D measurements by using a probe that touches various points on the basket surface. This technology can:

- Map the entire basket profile

- Measure multiple dimensions in a single setup

- Verify geometric tolerances like circularity and concentricity

- Generate detailed inspection reports

Optical Measurement Systems

For filter hole patterns and fine features, non-contact optical measurement systems7 are ideal. These systems:

- Capture images of the basket surface

- Measure hole diameters and spacing precisely

- Verify surface flatness and consistency

- Detect minor defects invisible to the naked eye

Measurement Protocol Comparison

| Measurement Tool | Accuracy | Best For | Limitations |

|---|---|---|---|

| Digital Calipers | ±0.02mm | Quick checks, basic dimensions | Operator dependent |

| Micrometers | ±0.001mm | Thickness measurements | Single dimension at a time |

| CMM | ±0.005mm | Complex geometry, full profile | Slower process, higher cost |

| Optical Systems | ±0.002mm | Filter holes, surface texture | Limited to visible features |

When discussing metrology with your manufacturer, I recommend requesting:

- A detailed measurement plan8 specifying which tools will be used for each dimension

- Sample measurement reports from previous similar projects

- Calibration certificates for their measuring equipment

- Gauge R&R (Repeatability and Reproducibility) studies for critical measurements

In my experience, manufacturers who are transparent about their measurement methods and willing to share detailed reports tend to produce more consistent coffee baskets. Don't hesitate to ask for specific measurement protocols for your most critical dimensions.

Can You Commit Cp/Cpk Targets for My Wall Thickness and Depth Features?

I once had to reject an entire shipment because the wall thickness varied too much, causing inconsistent extraction. Now I always discuss process capability metrics upfront to avoid these costly mistakes.

Yes, quality manufacturers can commit to Cp/Cpk targets9 for wall thickness and depth features, typically aiming for Cp/Cpk values of 1.33/1.0 for standard tolerances and 1.67/1.33 for critical dimensions. These statistical measures ensure consistent production quality beyond simple tolerance verification.

Understanding process capability indices is crucial when ordering custom coffee baskets. These statistical measures help predict how well a manufacturing process can meet your specifications consistently over time, not just for the initial samples.

Understanding Process Capability Metrics

Two key metrics to consider are:

- Cp (Process Capability): Measures the potential capability of a process to meet specifications, assuming the process is centered.

- Cpk (Process Capability Index): Measures the actual capability, taking into account how centered the process is relative to specification limits.

For coffee baskets, these metrics are particularly important for dimensions that affect functionality:

Wall Thickness Capability

Consistent wall thickness ensures uniform heat distribution and structural integrity. Variations can lead to:

- Uneven extraction

- Premature basket failure

- Inconsistent flow characteristics

Depth Feature Capability

Basket depth directly affects:

- Coffee dose capacity

- Headspace for expansion

- Extraction pressure profile

- Compatibility with tampers and distribution tools

Realistic Capability Targets

| Process Capability | Standard Value | Premium Value | Interpretation |

|---|---|---|---|

| Cp | ≥ 1.33 | ≥ 1.67 | Higher is better (potential capability) |

| Cpk | ≥ 1.00 | ≥ 1.33 | Higher is better (actual performance) |

| σ level | 3-sigma | 4-sigma | Statistical confidence level |

When negotiating with manufacturers, I've found it's realistic to request:

- For standard coffee baskets: Cp ≥ 1.33 and Cpk ≥ 1.0 for wall thickness and depth

- For premium precision baskets: Cp ≥ 1.67 and Cpk ≥ 1.33 for these critical dimensions

Implementing Process Capability Requirements

To effectively implement these requirements:

- Specify sample size: Request capability studies based on at least 30 production samples

- Define measurement points: Clearly mark where measurements should be taken

- Set monitoring frequency: Specify how often capability studies should be performed

- Request capability reports: Ask for formal reports with raw data and calculations

- Establish improvement targets: If initial capability is low, set targets for improvement

Remember that achieving high Cp/Cpk values may require additional setup time or process improvements, which could impact cost and lead time. However, the consistency you gain in your coffee baskets will typically justify this investment, especially for premium products where performance consistency is crucial.

How Will Deviations Be Handled Under My Control Plan and Drawing Notes?

I learned the hard way that without clear deviation handling procedures, suppliers might make uninformed decisions that compromise quality. Now I build comprehensive control plans that leave no room for misinterpretation.

Deviations from specifications are handled through a structured process defined in your control plan and drawing notes. This typically includes notification requirements, deviation classification (minor/major/critical), corrective action procedures, and disposition guidelines. Clear documentation helps manage variations consistently.

Establishing clear protocols for handling deviations is essential when importing custom coffee baskets. In my experience working with manufacturers in China, having a well-defined control plan prevents costly mistakes and ensures quality consistency.

Creating an Effective Control Plan

A comprehensive control plan for coffee baskets should include:

Deviation Classification System

Not all deviations have the same impact on functionality. I recommend classifying them into three categories:

- Critical deviations: These affect safety, compliance, or core functionality (e.g., incorrect food-grade material, rim diameter outside tolerance)

- Major deviations: These impact performance but don't render the product unusable (e.g., depth variation, minor wall thickness variation)

- Minor deviations: These have minimal impact on functionality (e.g., cosmetic issues, slight weight variation)

Response Requirements by Deviation Type

| Deviation Type | Notification Time | Documentation | Disposition Options | Corrective Action |

|---|---|---|---|---|

| Critical | Immediate (24h) | Detailed report + samples | Reject/Rework | Root cause analysis required |

| Major | Within 48 hours | Deviation report | Concession possible | Corrective action plan |

| Minor | Weekly summary | Listed in quality report | Accept with note | Process improvement |

Incorporating Control Requirements in Drawing Notes

Your technical drawings should include specific notes about deviation handling, such as:

- Notification requirements: "Supplier must notify buyer of any critical dimension deviations within 24 hours of detection"

- Approval process: "No deviations from critical dimensions permitted without written buyer approval"

- Documentation: "All dimension deviations must be documented in the FAI report with actual measurements"

- Sorting requirements: "100% inspection required for any lot with detected critical deviations"

Establishing Deviation Limits

For each dimension, consider specifying:

- Target value: The ideal measurement

- Tolerance range: The acceptable deviation from target

- Action limits: The point at which corrective action is required

- Specification limits: The absolute maximum/minimum acceptable values

For example, a rim diameter specification might read:

- Target: 58.00mm

- Tolerance: ±0.20mm

- Action limits: ±0.15mm (requires process adjustment)

- Specification limits: 57.80mm - 58.20mm (absolute reject outside this range)

Managing Communication Around Deviations

Clear communication channels are essential. I recommend:

- Establishing a single point of contact for quality issues

- Setting up regular quality review meetings (weekly during production)

- Using standardized reporting templates for deviations

- Implementing a formal deviation approval process

- Maintaining a deviation history database to track patterns

By establishing these systems before production begins, you can avoid the common situation where manufacturers make independent decisions about deviations that might compromise your product quality. Remember that cultural differences can influence how deviations are reported and handled, so explicit instructions are particularly important when working with overseas manufacturers.

Conclusion

When importing custom coffee baskets from China, understanding standard dimensions, tolerances, measurement methods, and deviation handling is essential for success. Clear specifications and open communication with your manufacturer will ensure your coffee baskets meet your exact requirements.

-

Understanding tolerance stack-up is essential for ensuring proper fit and function in custom coffee baskets. ↩

-

Identifying critical dimensions helps prioritize tolerances that affect functionality and quality. ↩

-

GD&T principles provide a comprehensive way to specify tolerances, crucial for high-quality manufacturing. ↩

-

FAI is vital for verifying that products meet specifications before full production, ensuring quality. ↩

-

CMMs offer precise 3D measurements, essential for ensuring the accuracy of custom coffee baskets. ↩ ↩

-

Digital micrometers provide accurate measurements for critical dimensions, ensuring quality in manufacturing. ↩

-

These systems allow for non-contact measurement, ideal for verifying fine features in coffee baskets. ↩ ↩

-

A detailed measurement plan ensures clarity on how dimensions will be verified, enhancing quality assurance. ↩

-

Understanding Cp/Cpk targets helps ensure consistent production quality, crucial for custom coffee baskets. ↩